Advancing micro-optics photometry for microstructured illumination plates

In the fast-moving world of micro-optics and automotive lighting, innovation doesn’t stop with fabrication – it also depends on accurate modelling and reliable photometry. Microrelleus, a specialist in advanced laser microstructuring and industrial engraving, knows this challenge well. With deep expertise in femtosecond and nanosecond laser technologies, the company supports a wide range of industries, and particularly the automotive lighting sector, where precision and performance must go hand in hand.

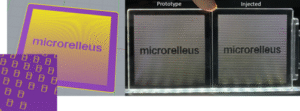

Like many companies working at the forefront of micro-optics, Microrelleus observed a recurring problem: a mismatch between the designed optical performance and the measured performance of fabricated parts. Whether the parts were directly engraved PMMA prototypes or injection-molded components created from engraved molds, the photometry results often drifted away from simulation predictions. To bridge this gap, Microrelleus turned to PHABULOuS for support in developing a standardized modelling and photometry approach as a valuable service for their customers.

Building a Common Language for Light

Microrelleus collaborated with PHABULOuS experts to define the essentials of a shared optical modelling workflow – one that would align software-based predictions with real-world measurements. The team set up a controlled test environment using an RGBW thin LED stripe to illuminate the edge of a 70×70 mm² plate. Light was coupled into the part and outcoupled through the micro-optical structures, generating a luminance pattern that could be precisely analysed and compared with simulation data.

To support this evaluation, Microrelleus supplied two flat micro-structured samples: a prototype and its injection-moulded counterpart. Multiple variables – including camera optics, LED intensities, LED colours, and measurement distances – were explored to fully understand how each factor influenced the correlation between simulated and measured optical performance.

|

|

| CAD file (left), prototype (center) and injected part (right) | |

Discovering What Light Reveals

The measurements confirmed two key insights. First, the injection-molded part exhibited slightly higher brightness than the prototype – a difference linked to increased surface roughness. Second, when a controlled level of roughness (modeled as Gaussian scattering) was introduced into the ideal CAD design, the resulting simulations aligned much more closely with the experimental luminance maps.

| Experimental measurement (left column) versus optical simulations (right column). Luminance maps in cd/m² (nits) in linear scale (top row) and logarithmic scale (bottom row) |

|

These findings mark an important step forward. They highlight not only the value of integrated modelling and photometry workflows but also the potential for future tools that help companies better predict real-world optical behavior before committing to full-scale fabrication.

Towards More Predictive, Reliable Micro-Optics Development

For Microrelleus, this work lays the foundation for a standardized modelling service that could help customers reduce development risks and innovate faster. The collaboration shows how combining simulation expertise with carefully designed measurement procedures creates a clearer picture of optical performance – one that aligns digital design more closely with physical reality.

With this approach, the future of micro-optics isn’t just about new structures and fabrication techniques. It’s also about making innovation more predictable – and more accessible – through the power of harmonized modelling and reliable optical testing.

|

““PHABULOuS and its partners have been a great support in developing a standardized modeling and photometry approach, so companies can close the gap between simulation and reality, reduce development risks, and accelerate innovation in micro-optics-enabled products.” Raúl García, CEO of Microrelleus |

|

| Project partners | |

|

|

Organisation