Next-Generation Retroreflectors for Automotive

G2 Industrial Engineering, an Austrian leader in advanced vehicle systems and automotive lighting, set out to reimagine one of the most established components in vehicle safety: the retroreflector. Their ambition was clear – use micro-optics to create a new generation of compact, highly efficient retroreflectors capable of returning light precisely to its source, even at small angles of incidence.

Pushing Beyond Traditional Retroreflector Design

Retroreflectors are essential in ensuring vehicle visibility, especially in low-light environments. Traditionally, they rely on millimetre-scale, cube-corner structures, requiring around 25 cm² of reflective area in passenger cars. While effective, these larger elements come with stringent manufacturing requirements, as even the smallest deviation can impact performance.

By turning to micro-optics, G2 Industrial Engineering explored a radically different approach. Instead of large cube-corners, their concept uses a periodic field of pyramid-shaped microstructures – each just up to 30 µm tall – arranged across a 1 cm² surface. This design not only maintains the required retroreflective function but also opens new aesthetic and integration possibilities for automotive designers.

The microstructure geometry was generated with a specialized algorithm and validated through optical simulation, demonstrating efficient reflection behaviour for low angles of incidence up to 20 degrees.

From Concept to High-Precision Micro-Optics

To bring the design into reality, the team followed a complete innovation chain – from simulation to origination, tooling, replication, and quality control.

- Origination: Using maskless grayscale laser lithography, the micro-structured patterns were written into a photosensitive resin, precisely modulated across the surface according to the calculated optical design.

- Tooling: A nickel-coated master was produced, serving as the durable inverse of the microstructure and forming the basis for replication.

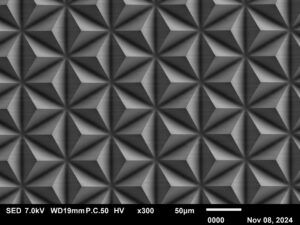

- Replication: UV imprint technology transferred the structures onto flexible substrates with high repeatability and accuracy. High-resolution imaging – through SEM and microscopic inspection – confirmed the fidelity of the replicated micro-optics.

|

|

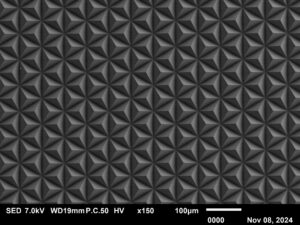

| High-resolution SEM images of the microstructures originated by MALA. | |

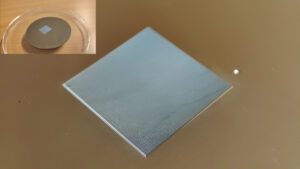

Photography of the Nickel tool.

|

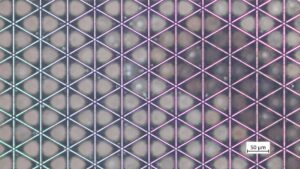

Microscopic close-up image of the retroreflecting structures.

|

Despite some deviations in the optical performance caused by non-optimized process parameters, the core retroreflective function was validated through simulation and fabrication, establishing a strong foundation for further refinement.

Towards Scalable Production

With the feasibility successfully demonstrated, G2 Industrial Engineering is now preparing for industrial-scale production of micro-optical retroreflector units. Strategic collaborations with key industry partners are paving the way for reliable, high-precision replication at manufacturing scale – an essential step toward bringing the technology into future automotive platforms.

Next steps include planning investments in tooling and production infrastructure, as well as qualification and certification for industrial applications. What began as a feasibility study is now evolving into a pathway toward fully scalable, micro-structured retroreflectors for next-generation automotive lighting.

A Small Surface With Big Impact

This work demonstrates how micro-optics can transform even the most established automotive components, enabling thinner, more elegant solutions without compromising performance. By merging advanced optical design with cutting-edge manufacturing, G2 Industrial Engineering is opening new horizons for automotive safety, lighting integration, and design freedom.

|

“Based on these results, G2 Industrial Engineering is now moving towards large-scale production of micro-optical retroreflectors. Thanks to collaboration with PHABULOuS and partnerships with important industry suppliers, this step will ensure consistent quality and precise manufacturing.” Dr. Albert Krammer, Head of R&D at G2 Industrial Engineering |

|

| Project partners | |

|

|

Organisation