PHABULOuS is the one-stop-shop and your gateway to a collaborative ecosystem driving innovation, excellence, and growth in micro-optics technology.

We bring together a complete value chain of Europe’s leading companies and research and technology organisations in the field of micro-optics. Our mission is to foster collaboration, accelerate technology development and enable the creation of innovative product and service solutions for customers.

By demonstrating the capabilities of this cutting-edge technology across diverse applications, we empower industries to harness the full potential of micro-optics. As the leading supportive organisation for the micro-optics community, we are:

- Uniting the micro-optics supply chain,from designers to manufacturers to integrators.

- Advancing cutting-edge micro-optics technologies for diverse applications.

- Facilitating knowledge-sharing, collaboration, and joint initiatives.

- Raising global awareness about the transformative potential of micro-optics.

Our partners

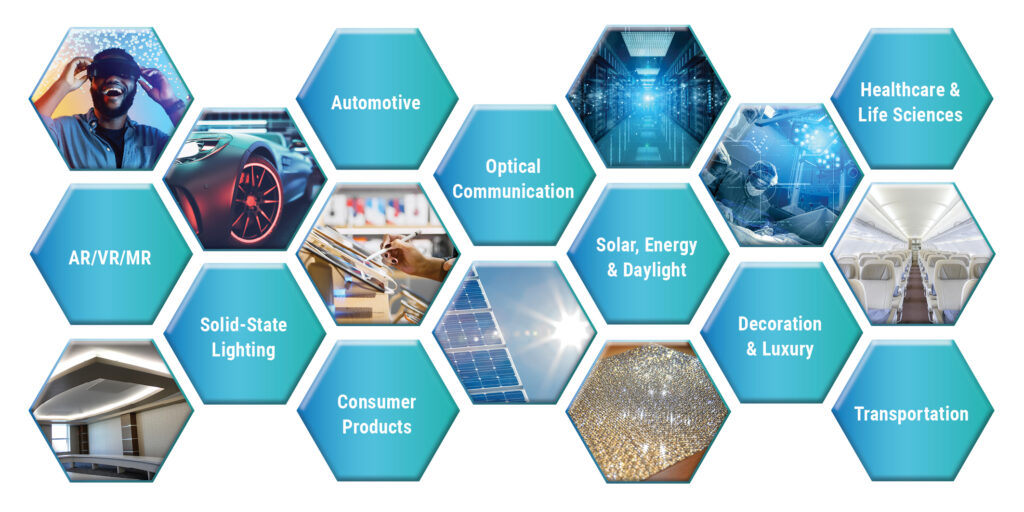

Markets

Micro-optics are revolutionizing how industries leverage light, enabling solutions that are smaller, smarter, and more efficient than ever before. With unparalleled precision and functionality, micro-optics provide transformative benefits across a wide range of applications.

Visit our market section of the website to learn more on how micro-optics is revolutionising many different industries.

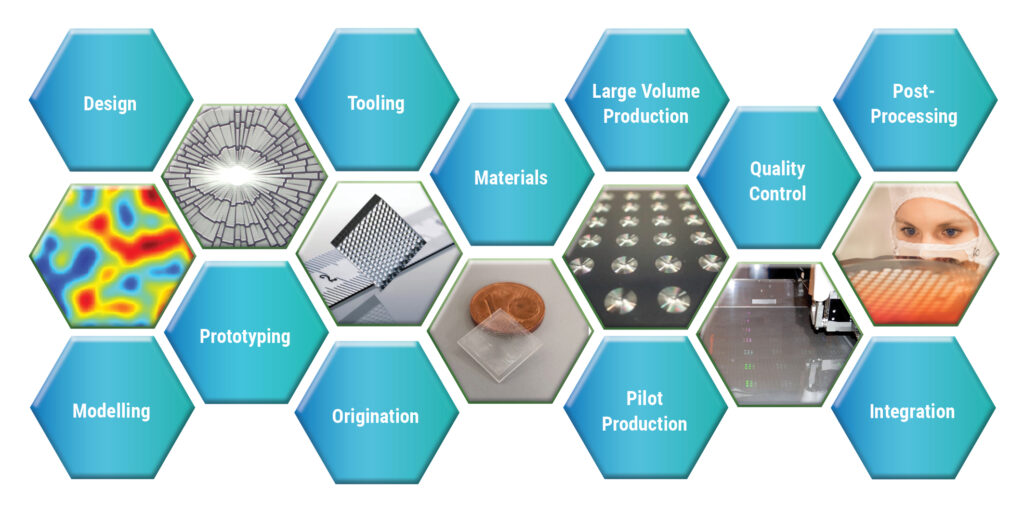

Technology

PHABULOuS offers access to cutting-edge solutions in micro-optics in different parts of the value chain, including advanced tooling, customizable materials, and precision manufacturing processes to facilitate breakthrough advancements and unlock the full potential of micro-optics.

Visit our technology section to learn more about the different technologies available through our ecosystem.