Technology

Micro-optics are revolutionizing industries with small, smart, and efficient solutions to leverage light, enabling new innovations with added precision and functionalities across a wide range of applications.

Micro-optics combine advanced materials, cutting-edge fabrication techniques, and precise engineering to manipulate light on a microscopic scale. This technology allows for the development of compact and lightweight optical components that enhance performance, improve energy efficiency, and reduce costs.

Advantages

- Miniaturization: Create smaller and more portable devices without compromising performance.

- Precision: Achieve unparalleled control over light for complex optical systems.

- Efficiency: Optimize light distribution and utilization for energy savings.

- Customization: Tailor solutions to meet specific requirements in diverse applications.

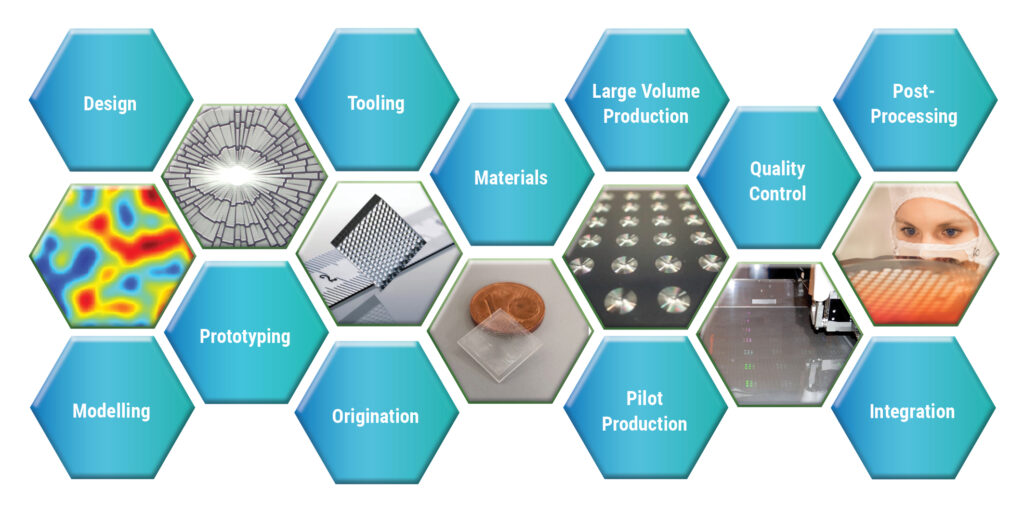

Precision at the core of production

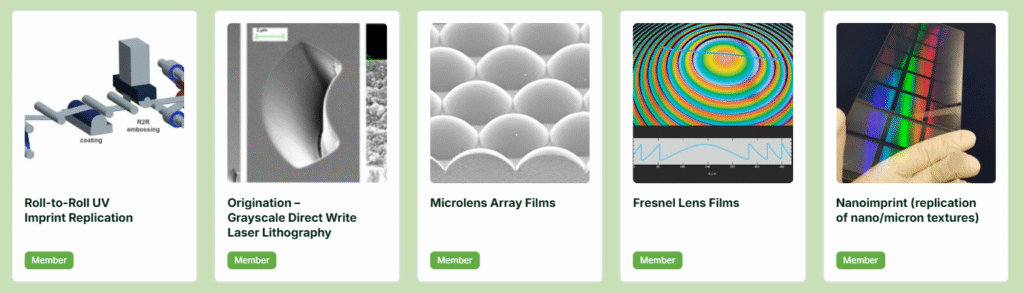

The manufacturing of micro-optical components demands exceptional precision and mastery of advanced technologies. From the replication of nano-structured surfaces to the shaping of complex freeform optics, manufacturing methods must balance scalability, cost-efficiency, and fidelity to design specifications. Our manufacturing solutions span state-of-the-art techniques like lithography, laser micromachining, glass molding, and nanoimprint lithography, enabling high-volume production with micron and sub-micron accuracies. With robust process control and material expertise, we ensure that every optical element produced meets the highest standards of performance, reliability, and reproducibility.

It starts with design for manufacturing

Every successful optical component begins with a design optimized to be manufacturable. Using advanced design software, simulation tools, and modeling services, we bring complex optical concepts to life. Our capabilities include ray-tracing, wave-optical simulations, and multi-physics modeling, enabling the prediction and optimization of optical behavior under real-world conditions. By accurately simulating the interplay between light, materials, and structures, we reduce development cycles, minimize prototyping costs, and ensure designs are manufacturable at scale while maximizing their performance.

From prototype to production

The transition from design to mass production requires high-fidelity masters and tooling. We specialize in the origination of master structures using advanced lithography, laser writing, and ultraprecision machining. These masters serve as the templates for high-volume replication processes. Our tooling solutions ensure the precise transfer of micro- and nano-scale features into production molds, allowing for scalable manufacturing without compromising optical functionality. By offering robust up-scaling strategies, we bridge the gap between innovation and industrialization.

The right materials for the right performance

Material choice is pivotal to the performance and durability of optical components. We support customers in selecting and developing materials tailored to their application needs, from high-refractive-index polymers to temperature-resistant glasses and hybrid composites. Our expertise spans mechanical, thermal, and optical property optimization, ensuring that materials are compatible with processing methods and end-use environments. Through careful material engineering, we unlock new performance levels for micro-optical systems.

Enhancing functionality through post-processing

To meet the demanding specifications of modern optical systems, components often undergo a series of post-processing steps. We provide precision coating, laser drilling, cutting, polishing, and functional surface treatments to enhance optical properties such as transmission, reflection, abrasion resistance, and hydrophobicity. Post-processing is crucial for fine-tuning optical performance, protecting delicate structures, and enabling integration into complex systems. Our solutions ensure that each optical component is fully optimized for its intended application.

Ensuring quality at every step

Quality assurance is embedded throughout our production process, from in-line monitoring to final inspection. Using advanced metrology tools—such as interferometry, profilometry, scatterometry, and functional optical testing—we verify critical dimensions, surface quality, and optical performance. Our rigorous quality control protocols not only ensure compliance with customer specifications but also provide data-driven insights for continuous process improvement. By maintaining tight tolerances and consistency, we guarantee the reliability and excellence of every component delivered.

Seamless integration into systems

The final step in realizing the value of micro-optical components is their effective integration into sub-modules or complete products. We offer tailored integration solutions, including optical alignment, mechanical assembly, bonding, and packaging, to ensure that optics perform optimally within complex systems. Our experience spans fields such as consumer electronics, automotive sensors, medical devices, and industrial instrumentation. Through seamless integration, we help transform discrete optical components into fully functional, market-ready solutions.

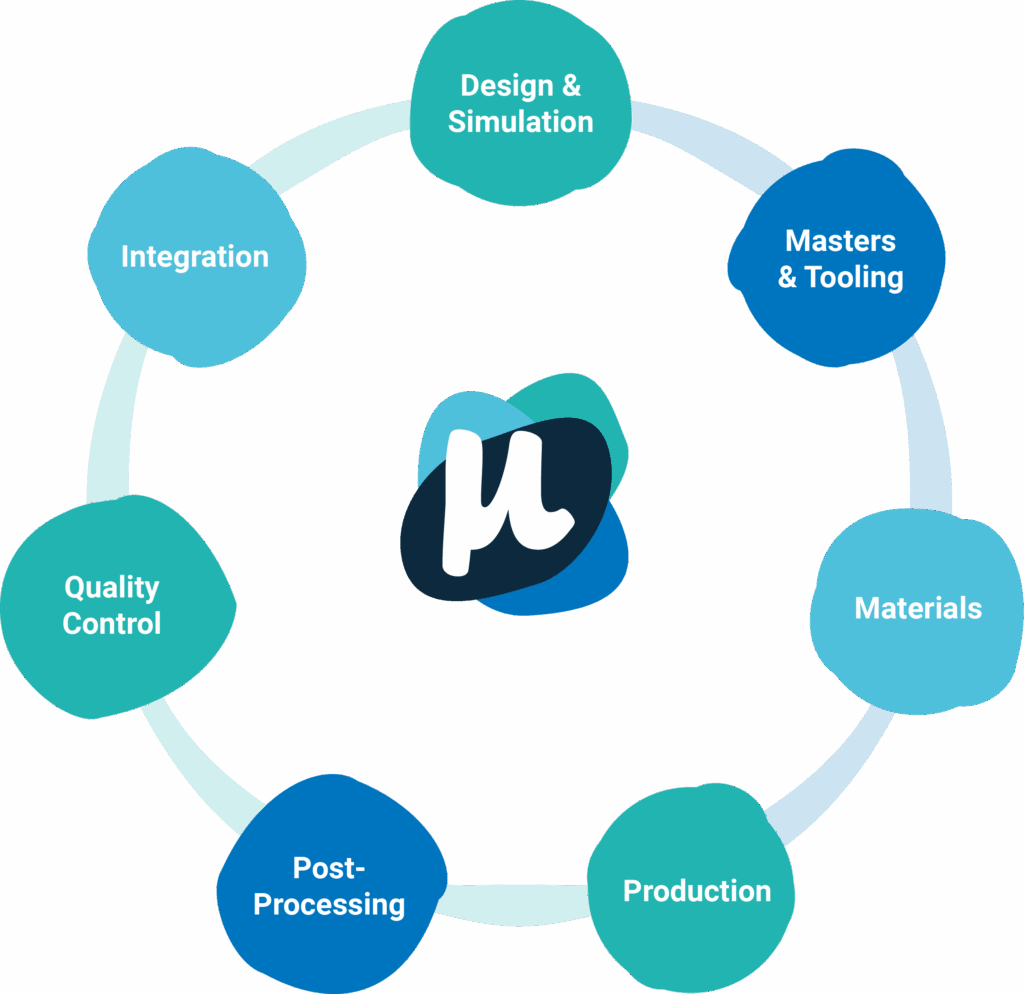

Your Gateway to the Complete Micro-Optics Value Chain

At PHABULOuS, we are the catalyst that seamlessly connects every stage of the micro-optics value chain — from concept to final integration. Acting as a single-entry point, we unify world-class expertise in design and simulation, materials selection, master and tooling origination, precision manufacturing, post-processing, quality control, and system integration. Whether you are still in the phase of initial development or ready to scale to high-volume production, PHABULOuS offers a streamlined path to bring your ideas to reality, ensuring efficiency, quality, and market readiness at every step. With our extensive network of partners and technologies, we make the entire micro-optics ecosystem accessible through a single, trusted platform.

Take a look at the capabilities of our ecosystem

Contact us to unlock to full potential of micro-optics

If you are looking to innovate, scale, or accelerate your micro-optics solutions, PHABULOuS is your ideal starting point. Through our extensive ecosystem of leading-edge partners, we ensure that you are connected to the right experts, technologies, and production capabilities to meet your specific needs. Whether your project requires advanced design support, specialized manufacturing, or complete system integration, we tailor the right pathway for your success. Get in touch with PHABULOuS today and discover how we can help you transform your optical innovations into market-leading products.