Advanced Micro-Optics for eProgressive Eyewear

- Markets:

- Consumer Products

- Healthcare & Life Sciences

Smarter sight through adaptive eyewear

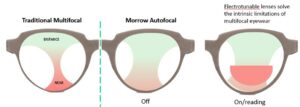

Traditional multifocal glasses require users to adapt to fixed optical zones for near and far vision. This often leads to discomfort, limited fields of view, and abrupt changes when shifting focus. Morrow sets a new standard by developing electro-tunable lenses that mimic the eye’s natural ability to shift focus smoothly, providing an effortless visual experience for activities at all distances.

Smart technology enabled by advanced micro-optics

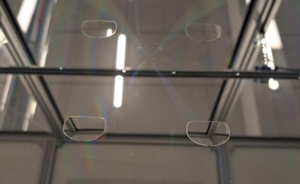

At the heart of Morrow’s technology lies a thin, flexible film with liquid crystals, embedded in a standard eyeglass lens. This film is a multi-layered structure, incorporating imprinted Fresnel-type micro-optics that guide light precisely through the lens. When a small electrical voltage is applied, the refractive index of the liquid crystal changes, adjusting the optical power of the lens in real time. The result is a pair of glasses that can instantly shift between near and distance vision modes — offering a wider field of view and significantly improved visual comfort.

| Moving towards cost-effective and scalable manufacturing

The objective was to move from wafer-scale prototyping to roll-to-plate replication, achieving a scalable and cost-effective manufacturing process for electro-tunable lenses. Through advanced mastering, replication, and post-processing techniques, the project demonstrated that free-form micro-optical designs can be produced reliably and efficiently at scale — a significant step toward the commercial potential and mass production of Morrow’s eProgressive lens technology. |

|

Integrating micro-optical design, advanced materials, and precision manufacturing opens the way to intelligent, responsive eyewear and new generations of smart optical devices for consumer markets.

| Project partners | |||

|

|

|

|